XCAM’s RIXSCam™ family of camera systems, consisting of the original RIXSCam™ and the RIXSCam™ Mini, combine the single-photon detection capabilities of custom EMCCDs with licensed centroiding technology to deliver sub-pixel resolution for RIXS (Resonant Inelastic X-ray Scattering) applications.

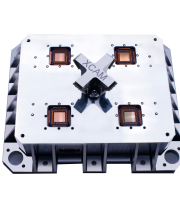

All the systems in XCAM’s RIXSCam™ range use the same custom EMCCDs – these are full-frame detectors with 1632x1608 16µm pixels which are back-illuminated with no AR coating to provide an outstanding soft X-ray response.

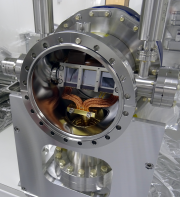

EMCCDs provide single-photon detection with sub-electron read noise. When cryogenically cooled down to temperatures in the range of -110 to -50 ˚C, as in the original RIXSCam™, dark current and associated dark current noise also becomes negligible, permitting a range of camera operation modes.

The RIXSCam™ system allows between one and three of these devices to be closely butted to provide a greater signal-to-noise ratio. The detector assembly is mounted on a rotatable cold bench which can be adjusted through all angles and locked in position from the outside of the camera, enabling the user to reduce the effective pixel size.

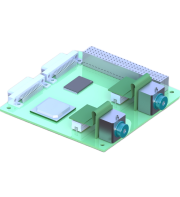

The RIXSCam™ Mini is a single-detector system which utilises a Peltier cooler and has a user-defined fixed gamma-angle for the detector. This allows the same spatial resolution as the larger RIXSCam™ system but at a lower cost to the customer. This is particularly beneficial to beamline scientists whose experiments do not require the same high-throughput as those requiring a multi-detector system. The detector mounting has also been designed to enable the detector to eventually be replaced if needed, providing a long-term economical solution for beamline scientists.

Finally, a centroiding algorithm, developed jointly by the Paul-Scherrer Institute (PSI) and the Open University, is applied to the resulting image, providing at output a ‘super-resolution’ image of up to 10 times the original resolution. This provides a resolution of better than 5µm, with better than 3µm having been demonstrated during experimental phases. The ultimate resolution achievable depends on the local experimental set-up as well as the camera system.

For more details please contact us today or download the RIXSCam™ and RIXSCam™ Mini product information sheets below.